Solution: Detecting Gas Leaks in Pipelines with TDLAS Technology

This article explores the use of Tunable Diode Laser Absorption Spectroscopy (TDLAS) technology for detecting gas leaks in underground pipelines. TDLAS is a highly sensitive and precise method that enables real-time monitoring of combustible gases, ensuring early detection of leaks and enhancing the safety of pipeline networks. The technology offers a reliable solution for industries looking to prevent potential hazards and optimize gas leak management.

Introduction

Natural gas is not only a critical energy source for daily life and city operations but also a vital component of urban public safety. As China's urbanization process accelerates, the expansion of city gas pipeline networks has increased significantly. The scale of these natural gas infrastructure systems continues to grow, with underground pipelines becoming increasingly complex. However, many cities focus heavily on above-ground facilities, often neglecting the scientific management of underground gas pipeline networks, leading to frequent gas pipeline safety incidents. These incidents pose serious threats to the safety and property of the public, highlighting the urgent need for enhanced gas pipeline safety management.By implementing advanced gas leak detection technologies like Tunable Diode Laser Absorption Spectroscopy (TDLAS), industries can better monitor gas distribution systems. The oil and gas industry requires more precise solutions for underground pipeline inspection, making smart pipeline monitoring essential for avoiding accidents. With rising demand for urban energy, smart gas management systems have become a key trend in pipeline safety across cities.

Current Situation: Urban Gas Safety "Explosions"

In 2021, a major gas explosion occurred in the Yanhu Community Market of Zhangwan District, Shiyan City, Hubei Province. The gas explosion accident was caused by severe corrosion and rupture of a natural gas pipeline. The leaked natural gas accumulated in an enclosed space under a building, and an exhaust pipe spark from a nearby restaurant triggered the explosion, resulting in significant casualties.In 2024, during the investigation of the Yanjiao 3.13 massive gas explosion in Sanhe City, Langfang, Hebei Province, experts noted that the town had introduced piped natural gas early on, leading to a complex underground gas network. Some of the older gas pipelines had been in use for over 20 years, with the deepest buried at 12 meters underground. The complexity of the network made it difficult to determine whether the leak occurred at a single point or multiple locations.Moreover, the 2023 National Gas Accident Analysis Report released by the China Urban Gas Association showed that there were 612 gas-related accidents nationwide, with 211 incidents involving gas pipeline networks, accounting for 34.5% of the total. Ensuring urban gas safety in underground pipeline systems and adjacent spaces remains a significant challenge for city safety management.

Solution

1. Customer Pain Points and Resolutions

- Reducing Labor Inspection Costs

Pain Point: Traditional gas leak detection methods, such as using soap water to find leaks, are inefficient and dangerous due to the high manual labor intensity.Solution: Optosky's automated monitoring system reduces the frequency and intensity of manual inspections, lowering labor costs and improving safety

- Addressing Complex Underground Gas Network Environments

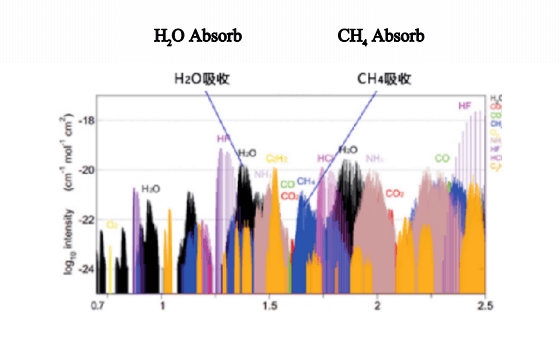

Pain Point: Conventional detectors using semiconductor or catalytic combustion technologies are easily affected by halogen and silicon-containing gases, causing sensor failure in complex underground environments.Solution: Optosky’s system is selective to methane, unaffected by other gases, humidity, or dust, making it ideal for monitoring underground gas networks.

- Enhancing Gas Pipeline Safety

Pain Point: Traditional leak detectors are limited to periodic inspections, unable to provide real-time monitoring or full coverage, which increases the risk of accidents.Solution: Real-time monitoring of pipeline conditions allows for early detection of potential hazards, significantly reducing accident risks.

- Accurate Methane-Specific Alarm Prediction

Pain Point: Detectors using NDIR sensors are prone to false alarms due to interference from water vapor, making them unsuitable for underground gas networks.Solution: Optosky’s technology is methane-specific, avoiding interference from water vapor and other gases, ensuring precise alerts.

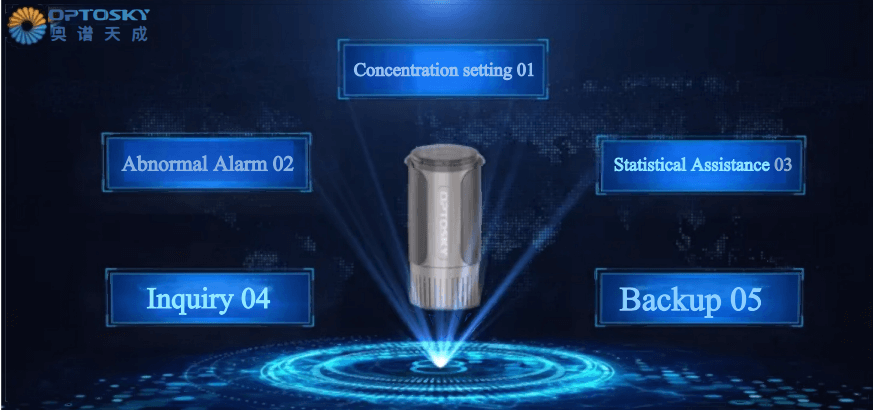

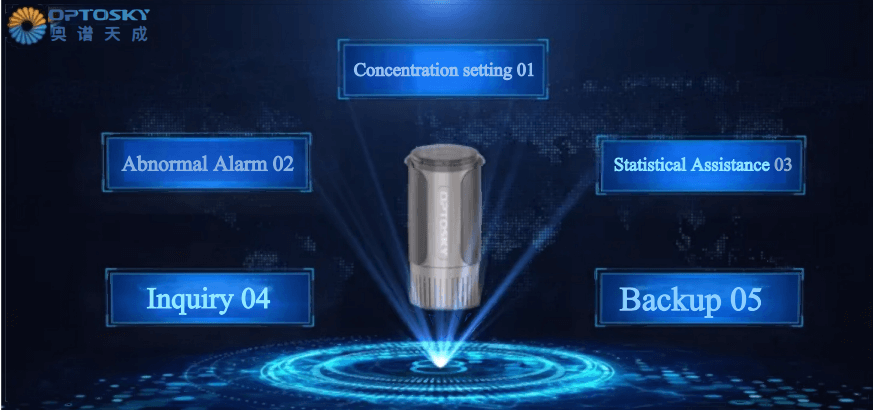

2. Smart Monitoring Platform

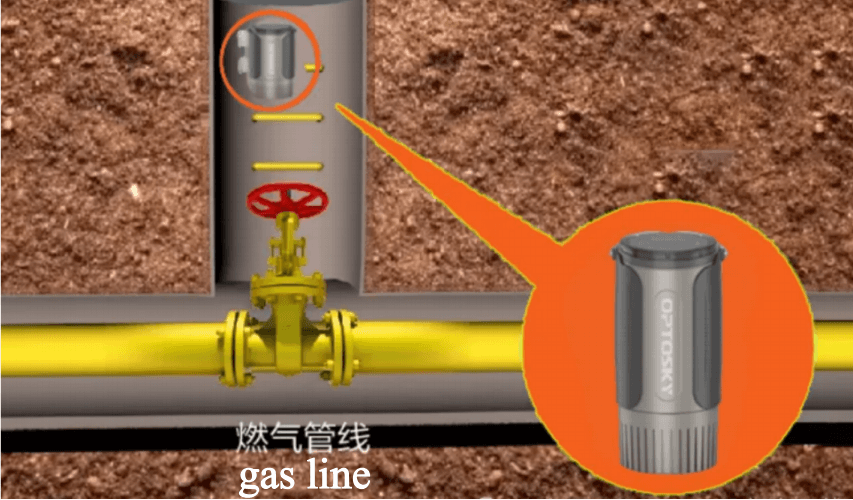

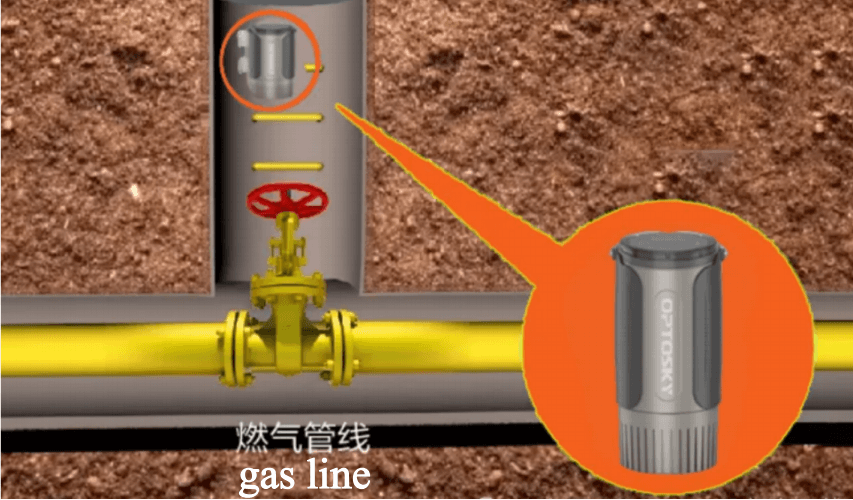

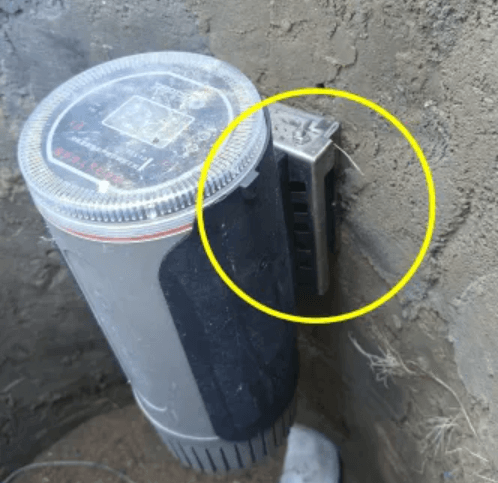

To ensure urban gas safety and overcome the challenges of gas leakage detection in underground pipeline networks, the Optosky R&D team has developed the GF200 Combustible Gas Leak Monitoring Device. This device provides real-time monitoring of gas leaks in underground pipelines, addressing the need for intelligent detection of gas leaks in complex underground environments.

Optosky's solution provides 7x24 continuous monitoring of the operational status of underground gas pipeline networks, collecting real-time data on pressure, temperature, and gas concentrations. This data is transmitted to a central supervisory platform for real-time analysis. Through this analysis, potential safety hazards such as gas leaks and abnormal pressure levels can be quickly identified.The system establishes a comprehensive, multi-layered, and integrated smart gas safety management platform, along with a collaborative emergency management mechanism involving multiple stakeholders. This enhances urban safety by improving comprehensive risk management and control for gas pipeline systems.

Product Introduction

The GF200 is a cutting-edge solution designed for monitoring and early warning of combustible gas leaks in urban underground pipeline networks. It utilizes TDLAS laser detection technology, high-reliability IP68 protection, intrinsic safety explosion-proof design, and internal moisture-proof processes. The GF200 is ideal for long-term use in underground spaces to monitor and alert for combustible gas leaks. It supports NB-IoT network transmission and seamlessly integrates with 3G/4G networks, enabling remote data uploads and alarm notifications.

Product Advantages

- Utilizes TDLAS technology combined with a point-type laser methane detection module.

- Methane-specific fingerprint features ensure exclusive detection, unaffected by other gases, water vapor, or dust.

- Multi-Layer Protection for Adaptive Complex Environments

The GF200 features an overall IP68 waterproof design, making it ideal for damp and water-prone underground environments. With an explosion-proof rating of ExibIICT4Gb and 672-hour salt spray corrosion resistance, this intrinsically safe device ensures reliable performance in hazardous locations. Powered by an explosion-proof battery, it offers stability and extended operational life (over 36 months in standard mode), making it well-suited for environments with varying pH levels in underground settings.

- Advanced Anti-Theft Measures

Integrated Beidou/GPS satellite positioning ensures intelligent anti-theft protection.

Available in stand-pole and wall-mounted installations for diverse scenarios.

Summary

Optosky stands on a foundation of technology, driven by market needs and focused on customer priorities, offering exceptional solutions across various sectors. By choosing the Optosky GF200, you are opting for safety and reliability. Let's work together to build a safer city.

Search

Categories

Popular Posts

Latest Posts

-100x100.jpg)

Comments: 0

No comments