Your shopping cart is empty!

Optosky Industrial Gas Emissions Monitoring Solution

Optosky's Industrial Gas Emissions Monitoring Solution delivers precise, real-time tracking of industrial emissions using advanced sensors and data analytics. It helps businesses meet regulatory standards, improve efficiency, and reduce environmental impact.

Background

With the depletion of coal resources and the increasing focus on refined coal processing, coal remains crucial in modern industries due to advances in technologies such as coal chemical processing, coal-to-gas, coal-to-liquid, and pulverized coal boilers. Despite these advancements, large thermal power plants still predominantly use pulverized coal boilers and spraying techniques to enhance coal efficiency. However, the coal pulverization process can lead to risks of combustion or explosions due to sparks and self-ignition. Monitoring indicators like CO (200 ppm) and O2 (12%) is vital for preventing explosions within pulverized coal mills.Gas analyzers play a key role in continuous monitoring of CO and O2 concentrations at the pulverizer outlet or in coal dust silos, ensuring both production and personnel safety. Effective industrial gas monitoring is critical for chemical plants to prevent accidents and safeguard workers, while also enhancing overall production safety and control capabilities.In industries like steelmaking, where processes involve flammable and inert gases, analyzing gas concentrations helps optimize production, ensure safety, and support energy recovery and environmental protection. Industrial gas analyzers are essential for various industrial applications, providing continuous measurement of gases such as CO, O2, and CO2 to maintain safety and efficiency across different operational conditions.

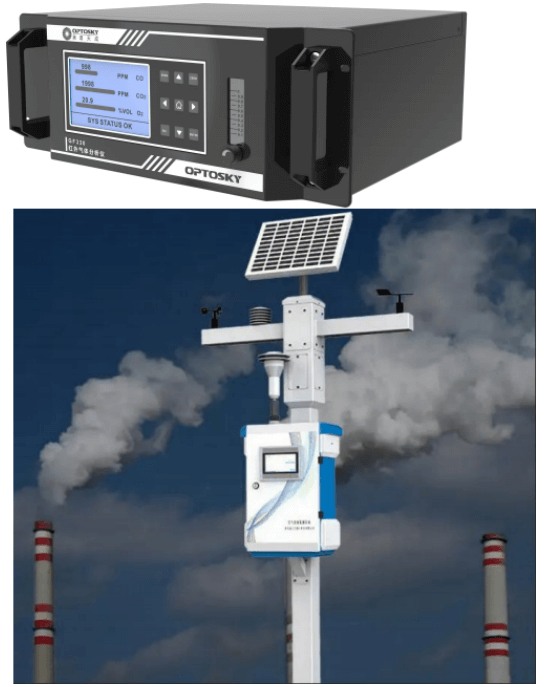

Product Introduction - GF330/GF360 Gas Analyzers

Features:- Continuous Measurement: The GF330/GF360 gas analyzers can continuously measure concentrations of gases including SO2, NO, CO, CO2, CH4, N2O, O2, and SF6.

- Simultaneous Gas Measurement: These analyzers can simultaneously measure multiple gas components, providing comprehensive analysis for industrial applications.

- Versatile Data Output: The GF330/GF360 supports various data output methods such as 4-20mA analog output, RS232, RS485, and Ethernet, ensuring flexible integration into different systems.

- Explosion-Proof and Non-Explosion-Proof Models: Available in both explosion-proof and non-explosion-proof versions, these analyzers are suitable for diverse industrial environments.

- User-Friendly Operation: With a simple interface and quick setup, the analyzers offer easy operation. The preheating time depends on the sensor used.

- Automatic Calibration and Diagnostics: Features automatic calibration, fault self-diagnosis, and stable performance, ensuring reliable measurements and maintenance.

- Large LCD Interface: The large LCD display allows direct menu-driven parameter settings, measurements, and calibrations for user convenience.

- Customizable Range and Units: Measurement ranges are customizable, and gas concentration units can be switched between ppm and mg/m³, catering to various industrial needs.

Application:

- Research Field: Laboratory Gas Monitoring and Analysis - Essential for precise and controlled experimentation, ensuring accurate results and safety in scientific research environments.

- Agricultural Field: Air Quality Monitoring in fruit storage rooms, cellars, and warehouses - Crucial for maintaining optimal conditions and preventing spoilage or contamination of produce.

- Industrial Field: Monitoring combustion systems for oil, gas, and coal - Includes tracking waste emission concentrations in applications such as incineration plants, petrochemical industries, metallurgy, and power plant flue gases.

- Environmental Protection Field: Air Quality Monitoring and carbon emissions tracking - Includes monitoring air quality, greenhouse gas emissions in industrial parks, urban carbon quantification, soil carbon flux, and forest carbon flux to support sustainability and regulatory compliance.

- Safety Field: Gas Composition Analysis - Vital for avoiding explosions and toxic gas leaks in mining, oil and gas stations, and petrochemical storage facilities, enhancing workplace safety and emergency preparedness.

Solution - Monitoring Technology

Tunable Diode Laser Absorption SpectroscopyTunable Diode Laser Absorption Spectroscopy (TDLAS) is a technique based on the Beer-Lambert law for gas absorption. This technology leverages the narrow linewidth of tunable semiconductor lasers and their wavelength shift in response to varying injection currents. By modulating the laser's wavelength to emit specific ranges of detection wavelengths, TDLAS enables the measurement of gas concentrations through the absorption of these modulated detection lasers by gas molecules. This advanced method provides highly accurate and sensitive gas concentration measurements, making it ideal for various industrial applications such as environmental monitoring, process control, and emissions analysis.Non-Dispersive InfraRedNon-Dispersive Infrared (NDIR) Technology is a method based on the Beer-Lambert law for gas absorption. This technology utilizes an infrared light source that emits infrared radiation. As this radiation passes through a gas sample of known concentration, the intensity of the absorbed spectrum changes proportionally to the gas concentration. By measuring the variation in spectral intensity, the concentration of the target gas can be accurately inferred. NDIR gas analyzers are widely used in various industrial applications such as emissions monitoring, air quality analysis, and process control. This technique is valued for its reliability and precision in measuring gas concentrations, aligning with current technical trends in environmental monitoring and industrial process optimization.

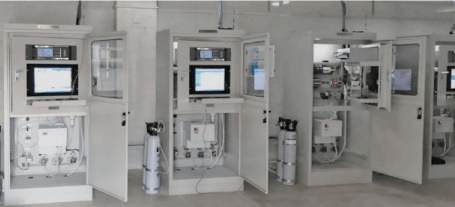

Solid Pollutant Source Monitoring

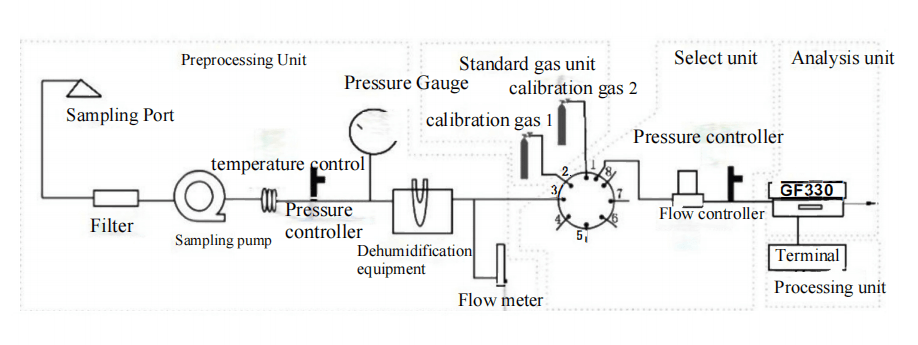

The GF330/GF360 gas analyzers, developed by Optosky, utilize Non-Dispersive Infrared (NDIR) Spectroscopy and Differential Optical Absorption Spectroscopy (DOAS) as core technologies. These advanced gas analyzers ensure high reliability, improved system stability, and enhanced control accuracy. Designed for fixed pollutant source monitoring, the GF330/GF360 is ideal for analyzing flue gas components such as NOx, SO2, CO, O2, and CO2. The analyzers use a direct extraction method combined with a dust filtration and water removal pre-treatment system, making them suitable for challenging environments like low temperatures and high humidity. They are known for their high measurement accuracy, fast response time, strong anti-interference capability, and long service life.The analyzers also offer data processing capabilities and can upload monitoring data to higher-level environmental protection agencies via the network, facilitating easy and efficient access to environmental monitoring data.Application:- Electric Power Industry

- Metallurgical Industry

- Cement Industry

- Petrochemical Industry

- Incineration

- Mining and Industrial Enterprises

Greenhouse Gas Monitoring

To achieve more accurate carbon emission data, greenhouse gases such as CO2 need to be precisely monitored, just like pollutants such as PM2.5. In soil ecosystems, carbon elements are primarily cycled through soil respiration, making accurate monitoring of CO2 emissions during soil respiration crucial for evaluating carbon sequestration processes in ecosystems.In line with the national "dual carbon" strategy, gas analyzers are essential for the greenhouse gas monitoring sector. These analyzers can continuously measure concentrations of greenhouse gases including CO, CO2, CH4, N2O, and H2O. Utilizing a direct extraction method combined with a dust filtration and water removal pre-treatment system, these analyzers offer high measurement accuracy, fast response times, strong anti-interference capabilities, and long service life.Application:- Carbon Emission Monitoring

- Atmospheric Monitoring

- Urban Carbon Emissions

- Soil Carbon Flux Monitoring

Refined Process Monitoring

In modern thermal power plants, pulverized coal boilers are used to enhance coal efficiency. However, the pulverization process can pose risks of combustion or explosions due to sparks and self-ignition. Monitoring CO and O2 levels is crucial for preventing explosions within these systems.

Gas analyzers are employed for continuous monitoring of CO and O2 concentrations at the pulverizer outlet or in the coal dust silo. Equipped with a dust filtration pre-treatment system, these analyzers detect even minor changes in CO and O2 levels, providing real-time data to operators. The system can also trigger pre-alarms based on preset threshold values, allowing for proactive measures to prevent potential fires or explosions caused by coal dust.

Application:- Coal Chemical Industry

- Pulverized Coal Processing

Search

Categories

Popular Posts

Latest Posts

-100x100.jpg)

Comments: 0

No comments