Your shopping cart is empty!

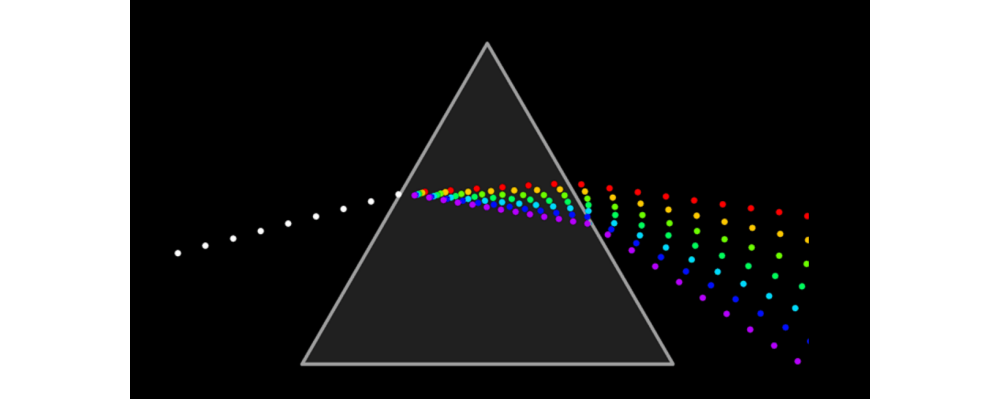

Spectroscopy: A Crucial Tool for Quality Control in Various Industries

Spectroscopy is essential for quality control across industries, offering accurate, non-destructive analysis to ensure product consistency, detect impurities, and meet standards in sectors like pharmaceuticals, food, and manufacturing.

In today’s competitive market, ensuring top product quality is essential. Spectroscopy has become a transformative tool for quality control across various industries, offering precise, real-time analysis. Its applications span sectors like food, pharmaceuticals, manufacturing, and environmental monitoring.

Food & Beverage

In the food industry, spectroscopy—especially near-infrared (NIR)—enables noninvasive analysis of moisture, fat, protein content, and contaminants. This helps ensure products meet safety standards and reduces waste, optimizing production processes.

PharmaceuticalsIn pharmaceuticals, techniques like UV-VIS and Raman spectroscopy ensure consistency and purity by measuring active ingredients and detecting impurities, safeguarding the quality of medications.

ManufacturingIn manufacturing, spectroscopy provides real-time insights into materials' chemical and physical properties. This is crucial for industries like plastics and automotive, where consistency directly affects product performance and reduces defects.

Environmental MonitoringFor industries concerned with environmental impact, spectroscopy offers fast, accurate analysis of soil, water, and air quality. It helps monitor pollutants and ensures compliance with environmental regulations.

ConclusionSpectroscopy’s precision and efficiency make it a critical tool for quality control, helping industries achieve higher standards of safety, consistency, and productivity. Incorporating spectroscopic solutions drives success in today’s demanding markets.

Search

Categories

Popular Posts

Latest Posts

Comments: 0

No comments