Coating Thickness Measurement

Availability: In Stock

Coating Thickness Measurement

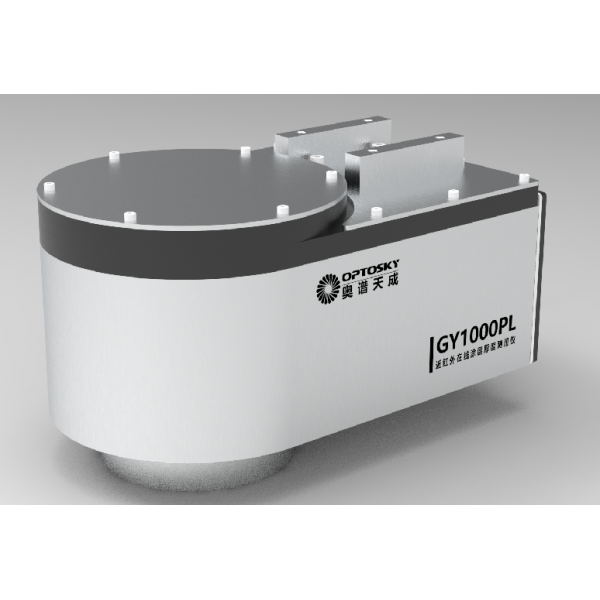

Product Code: GY1000PL

application

Description

The GY1000PL is a real-time, non-contact coating thickness measurement system using near-infrared spectroscopy.

It features an optimized optical system and advanced signal processing algorithms, combining Optosky's years of expertise in spectral analysis to provide a cutting-edge online coating thickness solution.

The GY1000PL includes a detection probe, display, power supply, and cables. The probe performs photoelectric detection and signal processing, while the display shows measurement results and provides a user interface.

Designed for industrial use, it offers data storage, alert functions, and networking capabilities with other industrial equipment to enhance production intelligence.

Features

- Non-contact, non-destructive, real-time online testing system.

- Replaceable halogen tungsten lamp with high luminous efficiency.

- PBS infrared detector for improved temperature stability.

- 4-wavelength, 8-beam technology for accuracy and stability.

- High-speed brushless motor for precise sampling.

- Dynamic dark current correction and digital filtering reduce noise.

- HD touchscreen with 30-day data storage.

- Modular design: one controller for up to 4 probes.

- Industrial-grade, dustproof, and waterproof.

- Easy maintenance.

Detection probe | ||

1 | Measurement indicators | Thickness/surface density (gram weight) |

2 | Measurement mode | Fixed-point measurement, mobile measurement |

3 | Measurement range | 10μm~1000μm |

4 | Light source | 12V/20W, life not less than 5000H |

5 | Measurement wavelength | 4 wavelengths, 8 beams |

6 | Detector | Infrared detector (PbS) |

7 | Repeat accuracy | ±1~2μm |

8 | Test speed | 25ms |

9 | Measurement distance | 250±100mm |

10 | Detection area | Diameter 50mm |

11 | Motor speed | 3750RPM/M |

12 | Lens window | Highly transparent quartz glass |

13 | Working temperature and humidity | Temperature 0~50℃ Humidity: 40%-60% |

14 | Probe cable | 3M shielded twisted pair, length can be customized |

15 | External interface | DC power socket |

16 | Input power | DC 24V/5A |

17 | Protection level | IP65 |

18 | Material | Aluminum alloy |

19 | Installation method | Hoisting and fixing |

20 | Dimensions | 348mm*200mm*197.5mm |

21 | Weight | About 15KG |

Monitor | ||

1 | Touch screen | 10-inch capacitive touch screen |

2 | Operating system | Windows 7 |

3 | Display content | Water content, status, etc. |

4 | Memory | 4G, external storage space can be expanded |

5 | Probe cable | 3M shielded twisted pair, support customization |

6 | External interface | DC power socket, network port, USB*2 |

7 | Physical button | Controller power switch |

8 | Protection level | / |

9 | Power input | DC24V/1A |

10 | Material | PC |

11 | Installation method | Lifting and fixing |

Packing list | ||

Standard configuration: 1 probe, 1 display, 1 cable, 2 sets of power adapter and power cord | ||